Firstly We have launched a new page to archive all our Jeep Content. Please join the community. CLICK HERE

There are several components in the front end suspension of a WK2 Jeep Grand Cherokee. Almost all of them are known to fail and can give you a clunking or knocking noise over bumps.

The following items are all known to give trouble and may be a contributor to these noises.

- Sway bar link pins

- Steering rack

- Front wheel bearings

- Front lower control arms

- Front upper control arms

- Front shock absorbers

- Front upper strut mounts

- Front Lower ball joint

We advise following this guide in order to diagnose and eliminate the noise before spending money simply replacing everything just to make this noise go away.

Step One: SWAY BARL LINK PINS

Remove the Front sway bar link pins from the vehicle. These are very common for failing and giving very loud banging noises. It is hard to believe that such a small item can be the cause of the noise, however often that’s all it is. Once they are removed go for a drive with them off the vehicle. Be careful, the body roll of the vehicle will be significant and it can be very off putting. If the noise is gone replace the links.

The Genuine Product is the best course of action, if available. If not, aftermarket options are suitable, however be mindful of products that use a nylon locking nuts. The nylon is fine and works well but don’t do them up with power tools. The heat generated can melt the nylon and you will still have noises.

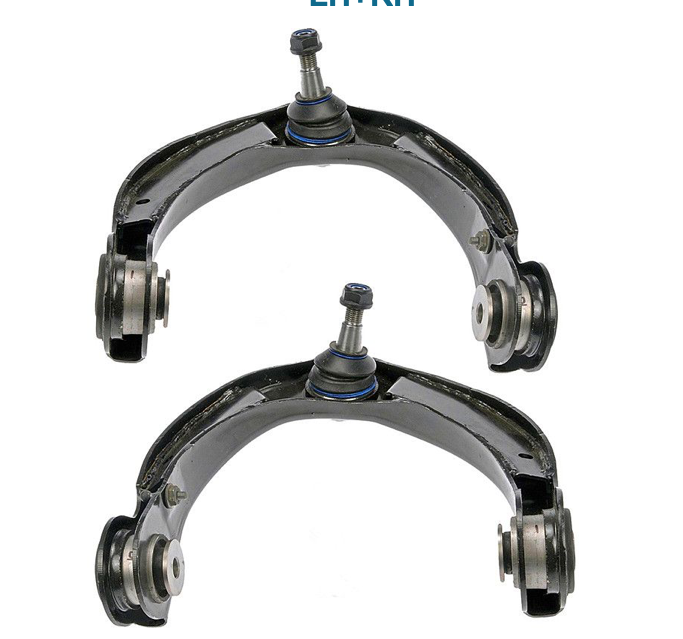

Step Two: BALL JOINTS & UPPER CONTROL ARMS

If sway bar link pins are not the source of the problem the next most common issue is either the lower ball joint, the upper ball joint or the inner bushes on the upper control arms. To Check these you need to jack the vehicle up in such a way that the suspension simulates the compressed position. That is to say you need to put the jack under the hub or lower arm and raise the vehicle while compressing the suspension. See image (note: image is not a WK2 but the principle is the same)

While the suspension is in the loaded position any movement in the ball joints (either upper or Lower) and the inner bushes on the upper arm will be easily noticed by grabbing the wheel at twelve o’clock and six o’clock and pushing the free play in and out. If there is free play one of the two joints is worn. You may need a second person to expect in order to determine which one.

In some cases a large pry bar under the tyre helps to exaggerate any movement.

With the suspension still in the loaded position grab the wheel at three o’clock and nine o’clock. Any movement here will wither be the inner bushes on the front upper control arms or movement in the steering rack.

STEP THREE: WHEEL BEARINGS Whilst the vehicle is still in the jacked position grasp the suspension spring with one hand and spin the wheel with the other. A faulty wheel bearing with allow vibration to transition through the suspension and you will feel a vibration sensation in your hand if you have a faulty bearing.

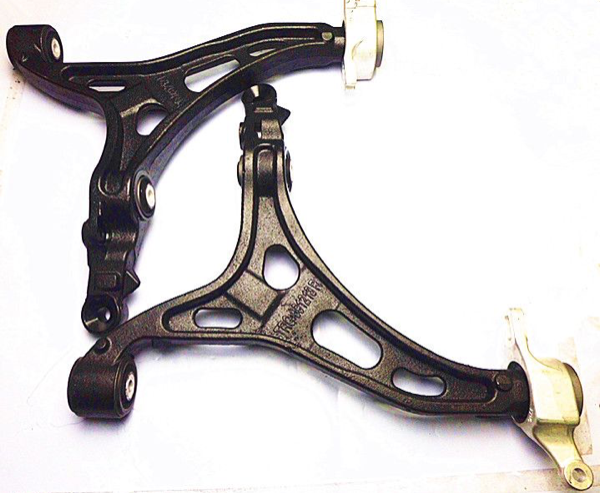

STEP FOUR: FRONT LOWER CONTROL ARMS.

The Lower control arm is common for the rear most bush splitting apart. Whilst hanging in the air on a hoist this may not be as apparent. If you can visibly see cracking in the rubber bush. They will need replacing. Below is a video we made on the wheel bearings and lower control arms.

STEP FIVE: FRONT SHOCKS & UPPER STRUT TOPS

If you have got this far and you have not found the source of the noise, chances are your issue is inside the shock absorber themselves and or the upper strut mount. We advise always replacing these as a pair. These are rather hard to 100% diagnose due to the internal bump stop design that Jeep has come up with.

We will say Genuine only for this product for a number of reasons.

- The aftermarket options never get the internal bump stop design right and new out of the box they can be very noisy.

- The mounting point of the shock at the control arm is a concave casting that inferior products have been known to fold over on themselves.

Below is an article we wrote a while back covering the front shock absorber design with the Jeep WK2.

Obviously if you have oil leaking from your shock absorber this is the first point of call.

STEP SIX: STEERING RACK

The final thing to look at if you have noises in the front end is the Steering rack. The rack is very common for external leaks but is not as well known for worn joints causing noise.

www.gdlauto.com.au https://gdlauto.com.au/blog/

https://www.facebook.com/GDLAutomotive

https://www.facebook.com/gdlsubaruparts

https://www.instagram.com/accounts/login/?next=https%3A%2F%2Fwww.instagram.com%2Fgdlautomotive%2F

https://www.instagram.com/accounts/login/?next=https%3A%2F%2Fwww.instagram.com%2Fgdlautoparts%2F

https://www.linkedin.com/in/dannie-ly…

https://www.tiktok.com/@gdl_autosport?