the latest news from Ford, particularly regarding the unveiling of the next-generation 2022 Ford Ranger. One of the standout features of this new model is the introduction of a 3.0 litre V6 diesel engine, adding a significant boost in power, torque, and overall capacity to Ford’s popular four wheel drive Ute line up, however this comes with some potentially catastrophic downsides.

The new 3.0 litre V6 diesel engine boasts promising performance figures, with 184kW of power at 3250rpm and a substantial 600Nm of torque within the range of 1750-2250rpm. Coupled with a 10 speed automatic gearbox and a permanent four wheel drive system.

A BIT OF HISTORY

While the diesel V6 is a new addition to the Ford Ranger line up, it’s based on the existing ‘Lion’ V6, marketed as a ‘Power Stroke’ diesel in American markets. This engine has a lineage dating back to 2004 and was previously utilized in the Land Rover Discovery 3 and 4 amongst other JLR offerings. Originally of a PSA Peugeot Citroën design for the Citroën C5 and also utilised by the Ford F-150 in the United States, boasting similar power and torque capabilities. We see a few issues with this choice in engine for Australia’s highest selling car, mainly being the litany of mechanical problems this design has had in it’s 20 year run and different iterations. Some of which repairs are quite excessive in labour for the service item. (I.E: removal of body from chassis to access a turbo or service a timing belt.) Some other common issues are:

CRANKSHAFT FAILURE

One of the primary reasons for failures in the Land Rover 3.0 TDV6 engine is attributed to crankshaft issues. The design of the crankshaft, being compact and narrow, creates vulnerabilities between the rod bearing journals and counterweights. These weaknesses are exacerbated not only during regular use but also by inadequate maintenance, aggressive driving habits, or sustained periods of heavy loads. In the images provided, it’s evident that crankshaft failure in this engine typically manifests as spun bearings, affecting both mains and conrods. There have been instances where the crankshaft has snapped at these vulnerable points. A tell tale sign of such a failure is often an audible knocking sound emanating from the engine.

Additionally due to a specific batch of crankshafts being improperly tensiled premature wear on the journal occurs. This premature wear causes the crush-fit bearing to exceed its tolerance, leading to a loose bearing on the journal. Consequently, the bearing rotates and obstructs the oil gallery, resulting in oil starvation and eventually leading to bearing seizure on the journal. The term “torque twist” is used to describe the crankshaft breaking. For instance, when a bearing seizes on the journal, it becomes rock solid. The subsequent downward force from the next piston combustion becomes so substantial that the crankshaft breaks at its weakest point, typically the lobe.

FUEL INJECTOR FAILURE

We’ve observed that certain fuel injectors installed in the 3.0 TDV6 engines tend to over-fuel. This refers to a situation where the injector injects an excessive amount of fuel into the cylinder, leading to heightened heat generation when the large fuel volume is compressed and ignited. The over-fuelling of fuel injectors in the 3.0 TDV6 engine leads to the melting and reduction of the piston due to the excessive heat it endures. This reduction in size, along with broken-off pieces altering the piston’s shape, renders it ineffective in maintaining compression or a proper seal within the cylinder. An identifiable sign of this issue is often a knocking sound from the engine. Additionally, the debris generated from this failure causes further damage.

TURBOCHARGER FAILURE

The turbochargers installed in the 3.0 TDV6 are often subject to wear, especially in vehicles with higher mileage. Additionally, they can become secondary failures following an initial engine issue. This occurs due to the decreased oil pressure during engine knocking; if the vehicle continues to be driven after such a failure, turbocharger failure is almost certain to follow.

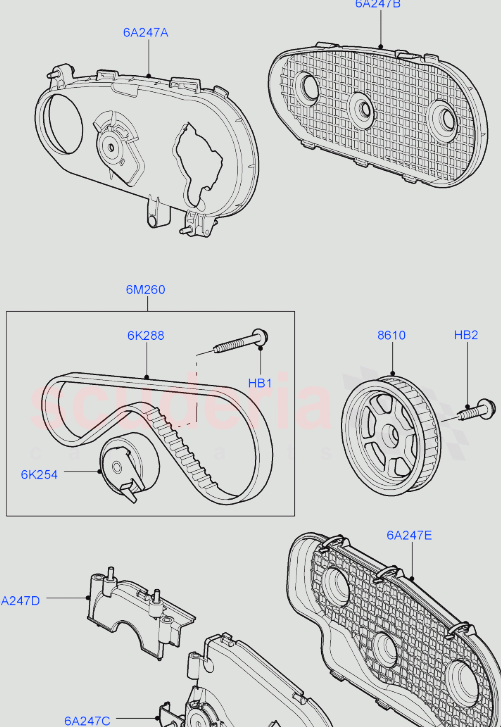

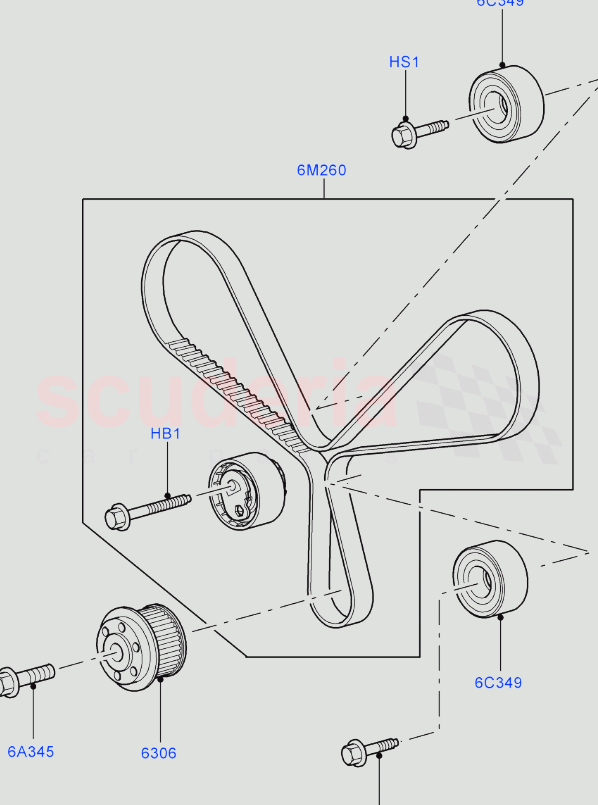

MULTIPLE TIMING CHAINS AND BELTS

There are multiple timing methods employed in this motor which can make servicing a nightmare depending on vehicle make and model, we shall see how they position it in the new Ranger. Will the belts on the back of the motor be accessible from the bonnet?

only accessible with the body off on the JLR offerings

The retirement of the Ford Ranger’s long-serving 3.2-litre, five-cylinder turbo diesel engine, along with the discontinuation of the manual transmission option, reflects the industry’s ongoing evolution towards emissions standards. However, the existing 2.0-litre four-cylinder turbo diesel engine will continue in both single-turbo and twin-turbo configurations, catering to varying performance requirements across the Ranger line up.

Ford’s decision to introduce a diesel V6 engine comes amidst competition from vehicles like the Volkswagen Amarok and Ram 1500, it will be interesting to see how fords V6 offering fares with competition from the RAM as one of Australia’s fastest growing vehicles.