After a lot of research and investigation I believe that we may actually have the answer to the cause for so many 3.0 Diesel engines failing in the Grand Cherokee.

This information was gained with collaboration with many mechanics and workshops across the world including an Eco Diesel performance shop in the USA and a survey carried out which included up to fifty individual cases where bottom end bearing failure has occurred. Participants in this survey were from Australia, USA and Canada.

The survey questions were design to determine if the failure related to vehicle use, servicing parameters or modifications. The results concluded that Oil grade, frequency of servicing or emissions modifications made no difference to the fault. There were are number of theories or possibilities that this survey was intended to try and either prove or eliminate.

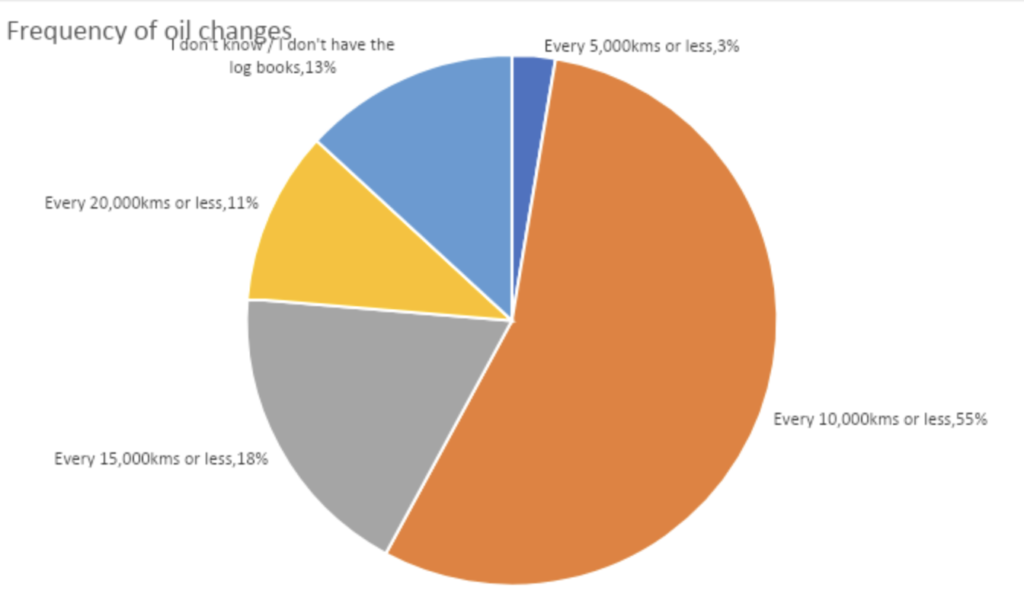

Oil Change frequency. The graph below shows that whilst most owners stay within the advised 10,000 km intervals, the frequency of oil changes did not prevent these engines from failing.

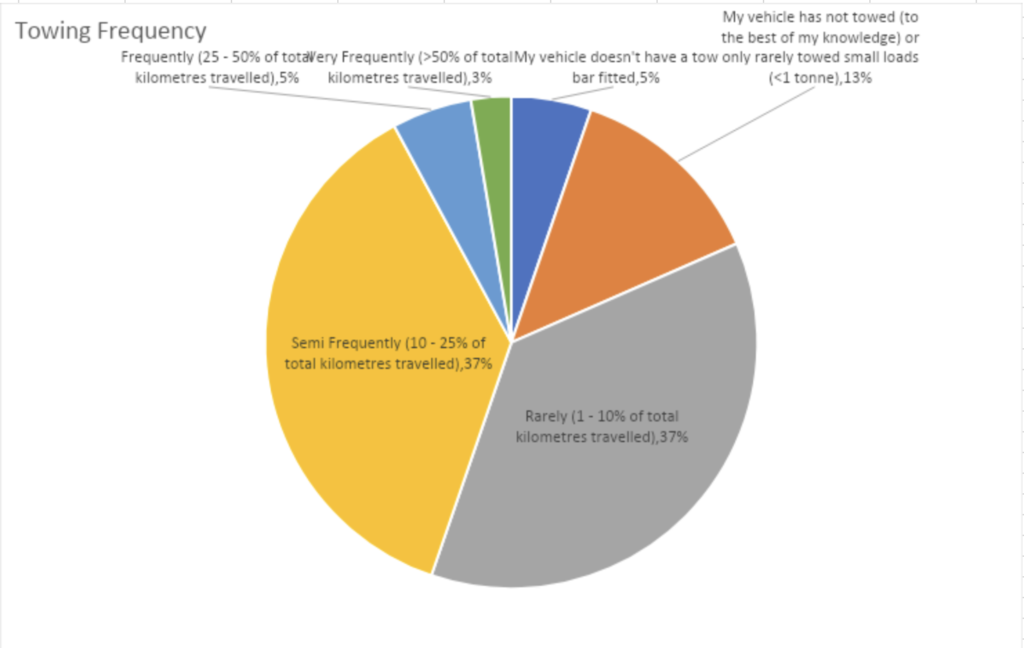

Towing: The theory presented by those working within the dealerships was that the fault was caused by excessive overloading when towing and owners “abuse” when towing. ie: Wide open throttle when hauling. The graph below shows that this is not the case as exactly 50% of engine failures had done little to no towing.

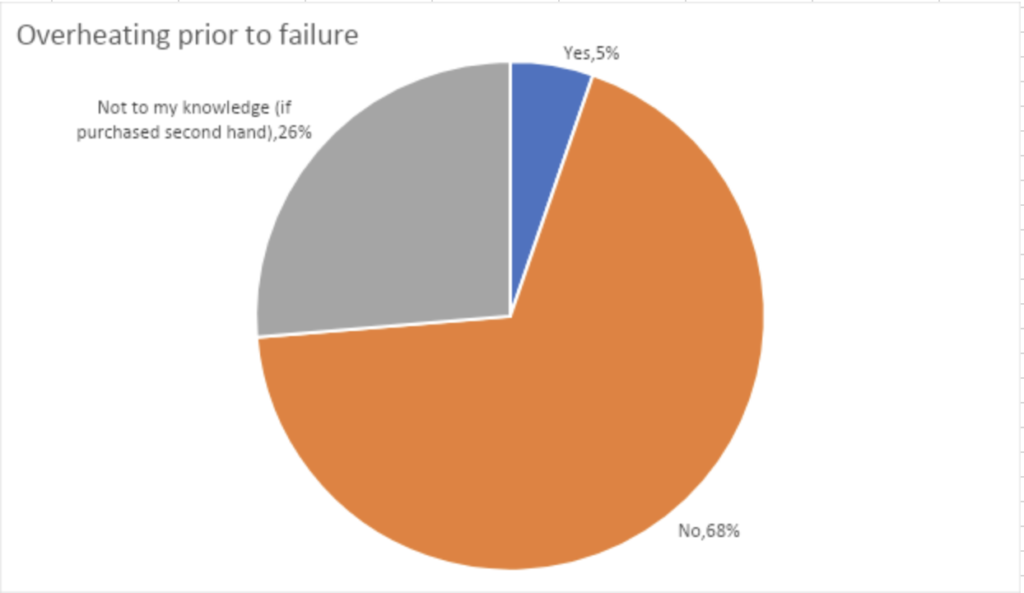

Overheat Issues: The 3.0 Diesel is known for overheating issues due to a number of cooling system issues ranging from the turbo coolant hose, the oil cooler and water pumps to name a few. A working theory is that once these motors had overheated they were in someway compromised and more susceptible to engine failure. The results below dismiss this theory as majority of owners did not experience an overheat issue prior to the failure.

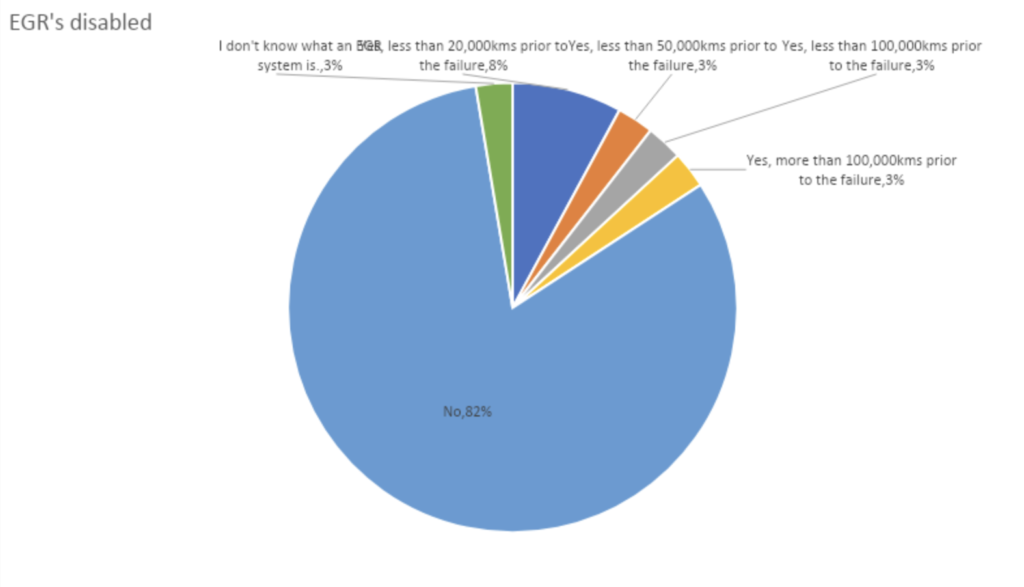

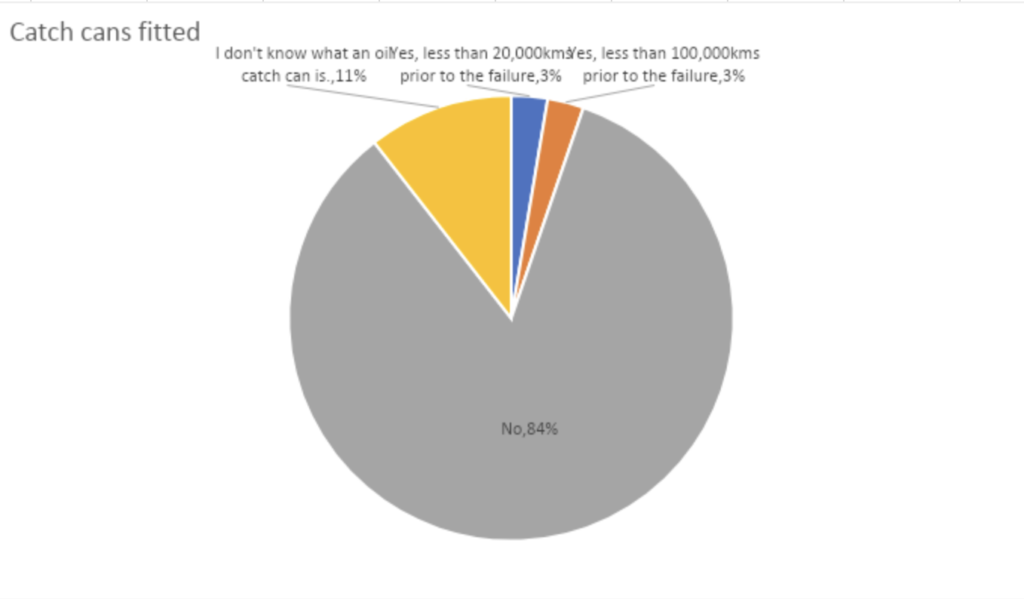

Modifications: The theory surrounding this was actually a twin theory. Some argued that the modifications such as EGR Deletes, DPF deletes and Catch Cans prevented the engine failures whilst others claimed it contributed to it. The data shows that it is possible that having these modifications made could reduce or prevent engine failure however the data does show that having them fitted is not the cause as majority of these failures occurred to un modified vehicles.

Engine tear downs and machine shop reports:

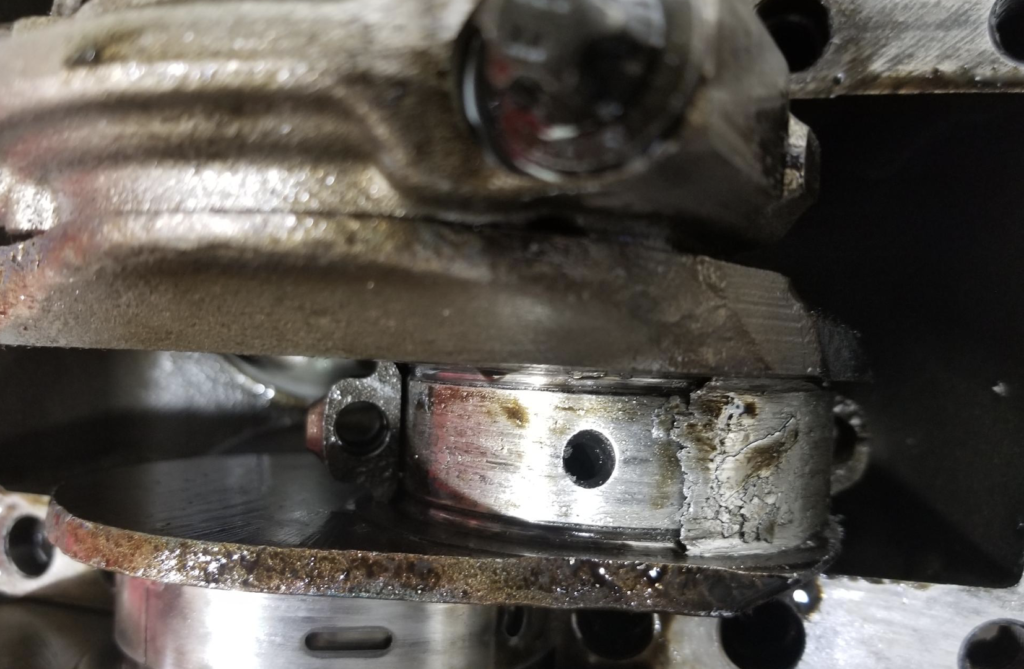

Throughout this research several motors have been stripped in both Australia and in the USA to inspect and report on the issue. The belief at the time was that the EGR valve was allowing an excess of carbon to be deposited back into the crank case which resulted in the oil galleries blocking up and thus starvation to the conrod bearings resulting in failure. None of the engines stripped and inspected after failure in either country had signs of oil gallery blockage or oil starvation.

What has been identified by an engine machine shop in the USA is what’s referred to Incorrect crank line bore. This means the crank shaft is not correctly aligned with the conrods This is only fractions of a millimetre but in an engine this is significant. This combined with low engine RPM or “lugging”(see below data on engine RPMs in vehicles fitted with 8Speed autos) causing additional and unbalanced load onto the big end bearings for conrods 5 and 4. When these engines fail it is consistently cylinder 4 and 5 that fail. No Failed motor stripped as part of this research had damage to any other bearings.

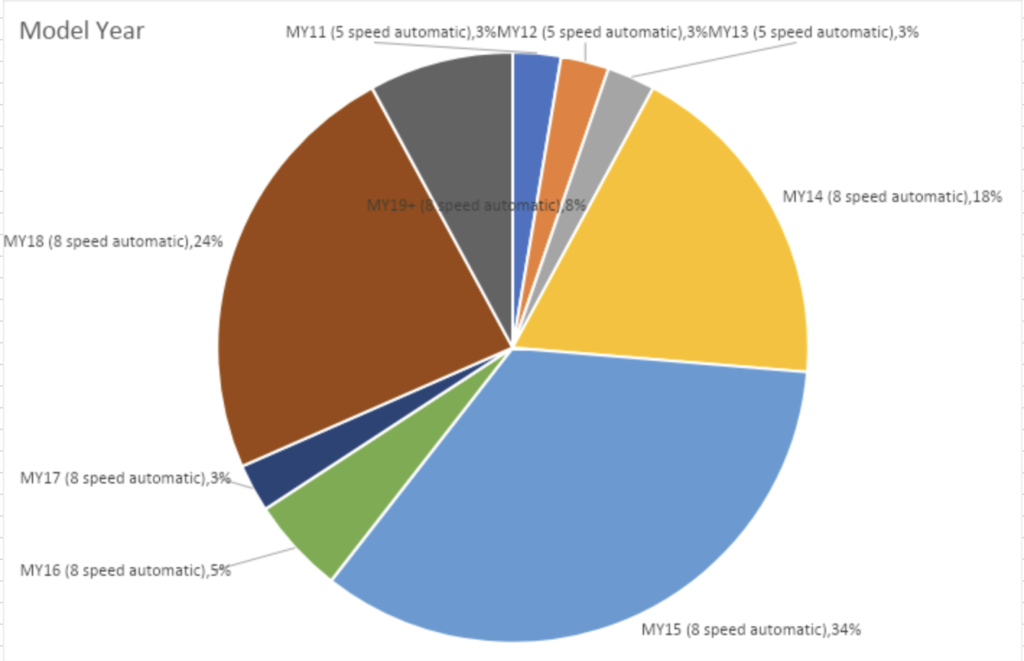

What’s interesting here and supports the conclusion made by the machine shops is the ratio of 5speed automatic transmissions to 8 speeds that have experienced the failure. 92% of Engine failures occurred in vehicles with the 8 speed automatic transmission.

Also note the reference to engine “lugging” which appears to exacerbate the defect. I feel this makes sense – as the data from the survey indicates the majority of failures occur on the ZF 8spd autos which have a lower engine speed at 100kmh in 8th versus the NAG1 5spd auto.

The conclusion at this stage is the fault is a design flaw in the manufacturing process and it is my opinion that the cause has nothing to do with the driver, the service history, how it was driven or any modifications made to the vehicle.

Why only some and not all engines?

The answer to this is believed to be around the transmissions. As previously established, the combination of this design fault and the engine RPM in the 8speed is believed to be the cause, however the driving style from one driver to the next is likely to mildly change. This means in any given engine the RPM at cruising speed will fluctuate from driver to driver. It would seem that vehicles driven more “aggressively” are less susceptible to the failure (there is no data to back this concept up)

At this stage this is a working theory of several mechanics and technicians within the auto industry across several countries, however none are mechanical engineers. Further action on this matter would require some professional blueprinting of several blocks both failed and not and a decent legal team.

The Video below shows Line boring been carried out on a different engine.